Recently, Prof. Lifang Liu in our college has made a breakthrough progress in the area of extraction of straw cellulose and its products development. The relevant research result was published in the world famous academic journal Industrial Crops & Products(Industrial Crops &Products 109 (2017) 241-247)in the title of “Effects of preparation methods on the morphology and properties of nanocellulose (NC) extracted from corn husk”.

At present, the utilization of straw in China is characterized by low utilization efficiency, low conversion efficiency, low economic efficiency and serious environment pollution. Cellulose is the main component of straw. Extraction and utilization of straw cellulose not only can realize the high-value application of straw, but also has great significance to environment protection. Nanocellulsoe is the cellulose crystal in nanoscale separated from cellulose raw materials, which can disperse in aqueous solution to form stable colloids. Due to its excellent properties, nanocellulose is widely used in many fields, such as daily chemical, biomedicine, papermaking, electronics, food, and environment. Although there are many researches about how to extraction nanocellulose from different cellulose materials, the effects of extraction methods on the morphology and properties of nanocellulose still has not been systematically studied.

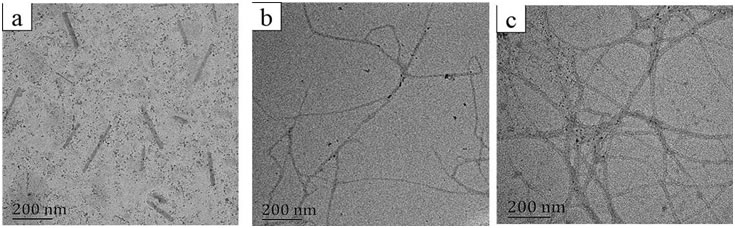

The morphology of AH-NCs, TO-NCs,and US-NCs

Therefore, Prof. Liu and Dr. Yang extracted three kinds of nanocellulose from corn husk by acid hydrolysis method (AH-NCs), TEMPO oxidation method (TO-NCs), and high intensity ustrasonication methods(US-NCs), respectively, and fully researched the effects of extraction methods on morphology, chemical composition, crystal structure, thermal properties and dispersion stability of the nanocellulose. The results showed extraction methods had obvious effects on the morphology and properties of nanocellulose. Among the three kinds of NCs, TO-NCs had the largest aspect ratio, and the best dispersion stability. However, its thermal stability was the worst. While, the AH-NCs had the highest crystallinity and best thermal stability with the smallest aspect ratio. US-NCs had the lowest crystallinity and dispersion stability. This research will have some direct meaning to the extraction method selection of nanocellulose.

The work was financially supported by Science and Technology Agency of Jiangsu Province (No.BE2014883 and No.XCL-063), Shanghai Municipal Education Commission (No.14ZZ071), Natural Science Foundation of China (No.51303021), and the Fundamental Research Funds for the Central Universities (No.16D310102).