Recently, Professor Xianfeng Wang from our collegehas made an important progress in the research of porous polyacrylonitrile nanofibrous membranes for postcombustion CO2 Capture. This work was published with the title of “Balsam-Pear-Skin-Like Porous Polyacrylonitrile Nanofibrous Membranes Grafted with Polyethyleneimine for Postcombustion CO2 Capture” in ACS Applied Materials & Interfaces, which is a world authoritative academic journal in the field of interfacial materials research(ACS Appl. Mater. Interfaces 2017, 9, 41087-41098).Donghua University as the only signatory, and the first author of this paper is adoctoral student named YufeiZhang.

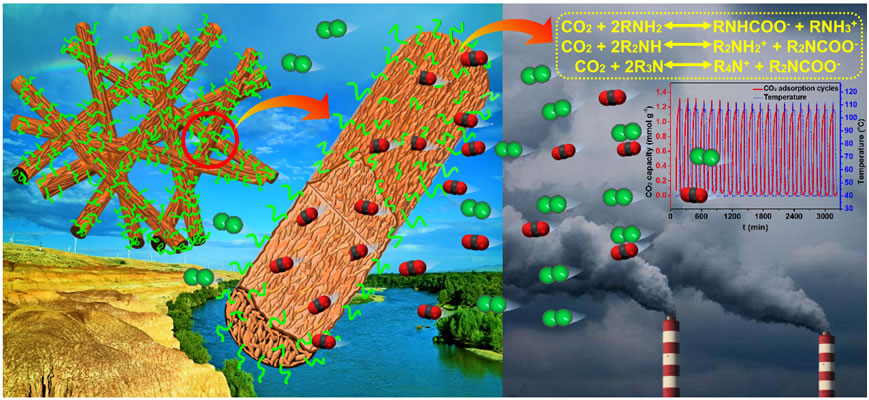

Schematic illustration of porous polyacrylonitrile nanofibrous membranes grafted with polyethyleneimine for postcombustion CO2capture

Massive emissions of carbon dioxide (CO2) worldwide hascaused severe global warming, a rising sea level, and a series ofenvironmental problems, which is an alarming threat to theenvironment and public health.Therefore, CO2 capture hasbeen given tremendous attention, and it is urgently necessary todevelop carbon capture and storage (CCS) technology toreduce global excessive CO2 emissions. Amine-containing sorbents have been extensively studiedfor postcombustionCO2 capture, however, most sorbents are in the form of particles or powders, causing issues such as blocking of the pipelines andrecycling problems during the flue gas separation. For asolution to these problems, it is essential to develop flexible,continuous, and robust solid sorbent materials with porousstructures for postcombustion CO2 capture. Electrospun nanofibrous membranes would be an ideal CO2 adsorption materialdue totheir outstanding features such as low cost, large surface area,easy-to-design pore structure, goodcontinuity and flexibility, as well as easy functionalization, etc.

Therefore,the researchers developedflexible, robust, and polyethyleneimine-grafted (PEI-grafted) hydrolyzed porous PAN (HPPAN-PEI)nanofibrous membranes throughthe combination of electrospinning, pore-forming process, hydrolysis reaction, and the subsequent grafting technique. The resultant HPPAN-PEInanofibrous membranes exhibit a balsam-pear-skin-likeporous structure, which isan excellent CO2adsorption material. Because of the hierarchical pore structure andgrafting of amine groups, the HPPAN-PEI NFMs are endowed with a CO2 capacity of 1.23 mmol/g at 40℃, excellent CO2/N2selectivity (27), good thermal stability, the tensile strength up to 11.1 MPa, and the CO2 capacity retains 92% of the initial value after 20 adsorption-desorption cycle tests, indicating that the resultant HPPAN-PEI nanofibrous membranes can be potentially applied to efficientpostcombustion CO2 capture.Therefore, this work provides a new idea for fabricating nanofibrous membrane-based solid adsorption materials endowed with a porous structure applied to CO2 capture.

This work was supported by the National Natural Science Foundation of China, the Shanghai Committee of Science and Technology, theShanghai Rising-Star Program, theNational Key R&D Program of China, andthe Fundamental Research Funds for the Central Universities.