Recently, the research group named “Functional nanofibrous materials” led by Prof. Bin Ding in our college has made a new breakthrough in the fabrication of fluorine-free superhydrophobic waterproof-breathable membranes.This work was published with the title of “Robust fluorine-free superhydrophobic amino-silicone oil/SiO2 modification of electrospun polyacrylonitrile membranes for waterproof-breathable application” in ACS Applied Materials & Interfaces, which is a world authoritative academic journal in the field of interfacial materials research(ACS Appl. Mater. Interfaces 2017, 9, 15139-15147.).

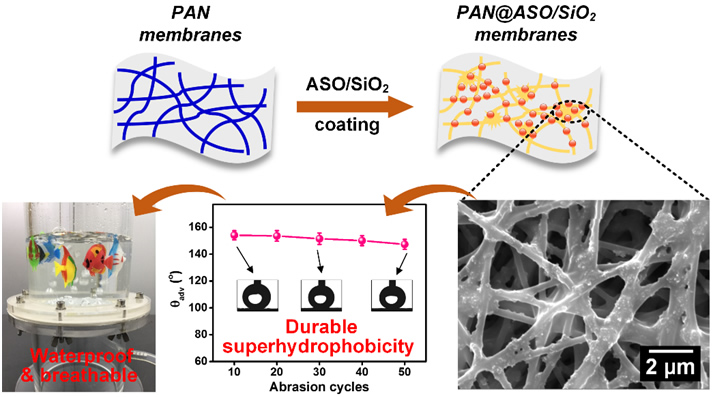

Schematic illustrationof the fabricationof thefluorine-free superhydrophobic nanofibrous membranes and the waterproof-breathable performance demonstration.

Waterproof-breathable functional membranes can not only protect the wearer from external rain and snow, but also provide a good level of comfort, which have been used in various applications including outdoor protective clothing, military clothing and health care materials.Currently, the commercial fluorinated waterproof-breathable membranes provided relatively good waterproofness and breathability. However, the bioaccumulation, environmental persistence, and toxic potential of fluorinated compounds limited their applications. Therefore, developing the fluorine-free functional membranes is the important tendency of waterproof-breathablemembranes. In addition, superhydrophobic waterproof-breathable membranes have caught interest of numerous investigators in the fields ofself-cleaning, anti-icing, and outdoor tents.

So the researchers prepared robust superhydrophobic electrospun PAN membranes via dip-coated by amino-silicone oil (ASO) and blade coated with SiO2 nanoparticles. The introduction of ASO and SiO2 nanoparticles constructed the multi-hierarchical rough structure withlow energy, which resulted in superhydrophobicity(water contact angle of 162o) of the modified membranes.At the same time, the SiO2 nanoparticlesnot only dispersed on the nanofibers, but also covered the pores among the nanofibers. This phenomenon further decreased the pore size of the modified membranes, which resulted in improving the waterproofness while maintaining a relatively good comfort:high hydrostatic pressure of 74.3 kPa, modest moisture vapor permeabilityof 11.4 kg m-2 d-1and air permeability of 20.5 mm s-1. Furthermore, the inorganic-organic hybrid coating of ASO/SiO2 nanoparticles imparted the membranes with durable superhydrophobicity even after 40 abrasion cycles, and retain their water repellent properties when exposed to harsh acidic and alkali conditions (pH:0-12). The durability also amplified the applications of the modified membrane in protective clothing in the extreme environment.

This work was supported by the National Natural Science Foundation of China, the Shanghai Committee of Science and Technology, the Fundamental Research Funds for the Central Universities, and the “DHU Distinguished Young Professor Program”.