Recently,researchers in Department of Nonwoven Material and Engineeringreported important progresses in the development of lithium-ion battery separators based on nonwoven skeletons. Thework has been published in Journal of Materials Chemistry A, a well-known journal from the Royal Society of Chemistry (J. Mater. Chem. A, 2017, 5, 311-318).

As a key internal component of Lithium-ion battery, separator directly affects the performance of battery capacity, cycle time and service life. Among various separators, Poly(vinylidene fluoride) (PVDF) microporous membrane has been intensively researched, owning to its high porosity and affinity to electrolyte. However, practical applicationof such membranes has been hampered due to the insufficient mechanical strength, low melting point and structural instability.

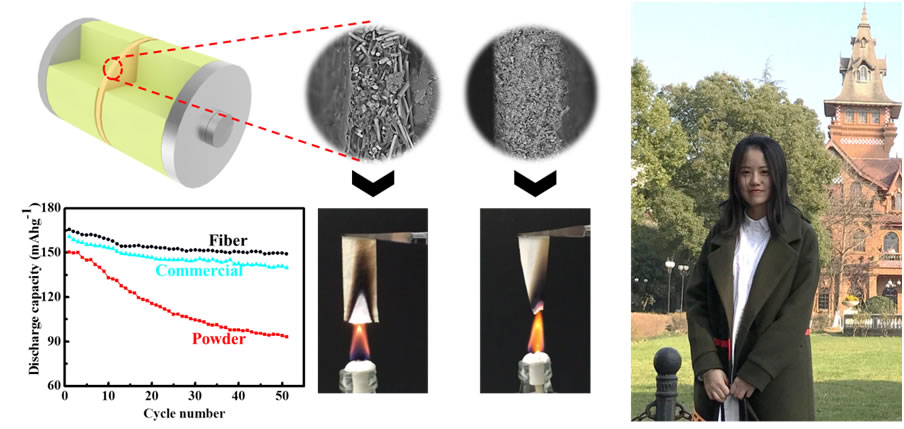

To solve these problems, the authors designed and prepareda separator based on inorganic nonwoven skeleton.Through a wet laying process, PVDF-HFP membrane and inorganic staple fiberswere uniformly casted into a thin membrane. Compared with the commercial polyolefin separators,the electrolyte absorption height of separators containing 75% inorganic fibers increased significantly.Further comparison with powder separator under the same component suggests that the mechanical properties of the fiber separator improved greatly underbothdry and wet state. More attractively, the reinforcement effect of the nonwoven skeleton endows the fiber separatorwithexcellent flame resistance and structural stability under intensive combustion.

Because of theseadvantages, electrochemical properties of the batteries based on fiber separator were alsosignificantly improved under room temperature and elevated temperature. The battery capacity retention rate is ~93% after the charging and discharging for 50 times at room temperature, and the open circuit voltageat 140℃can be well maintained throughout the testing time.

Structure and performances of battery separator based on staple fiber nonwovens, and a photo of the first author

The research work was supported by the National Natural Science Foundation of China and Key Laboratory of Textile Science &Technology. The article was published with Miss Meina Wang as the first author, who has obtained a master degree in Nonwoven Materials and Engineering this March.