Recently, the research team named “Functional Nanofibrous Materials” led by Prof. Bin Ding in our college has made a breakthrough progress in the area of effective protein adsorption materials. They successfully fabricated protein adsorption nanofibrous membrane materials by the combination of forefront eletrospinning technology and in situ polymerization. The resulted materials exhibited fast equilibrium and high adsorption capacity to lysozyme because of the fine fiber diameter, high adsorption ligand density, narrow pore size distribution, as well as highly connected tortuous porous structure. The relevant research achievement was published in the world authoritative academic journal in the field of materialinterfacesresearch (ACS Appl. Mater. Interfaces 2015, 7, 15658-15666) on the title of “Highly Carbonylated Cellulose Nanofibrous Membranes Utilizing Maleic Anhydride Grafting for Efficient Lysozyme Adsorption”.

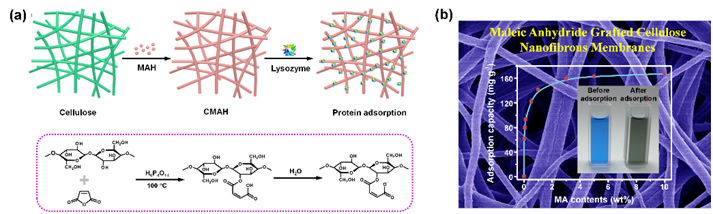

(a) Schematic showing theprocess of the fabrication andlysozyme adsorptionof MA nanofibrous membranes, and (b) their protein adsorption performance.

In recent years, proteinswith high purity are urgently required in variety of areas, involving bio-pharmaceutical, immunodiagnostics and immunotherapy, scientific research. Highly purification process is the key step for theproduction of proteins since it directly determines the purity and productive efficiency of protein products. Nowadays, chromatography resins are the mostly used materials for protein separation and purification, while they generally suffer from the disadvantages of relatively slow adsorption kinetics, high operation pressure drops and long operation time due to the slow mass transfer rate of proteins in the materialssince most of the adsorption ligands are distributed in the interior of these porous resin beads materials, caused their disability to meet well with the demand of the large scale and high speed industrial protein productions. Alternatively, fibrous membranes adsorption materials with large pore sizes could effectively decrease the using pressure-drops, but their small surface areas and low ligands distribution density caused by their relatively large fiber diameter seriously restrict their application in the industrial productions.

Therefore, the researchers greatly increased the amount of active hydroxyl on the fiber surface and then got superhydrophilic cellulose nanofiber membranes together with good mechanical strength via the precise control of deacetylation process. Furthermore, they modified the obtained membranes by taking the bifunctional carboxyl coupling agent as the modification materials, then negative carboxylswerein situ grafted on the surface of nanofibers, which endowed the materials with effective protein adsorption and purification performance. The resultant materials exhibited a high lysozyme adsorption capacity of 160 mg/g, fast equilibrium within 12 h, and excellentreusability.Otherwise, the saturation dynamic adsorption capacity of the membranesunder the drive of gravity reached up to 118 mg/g, which has a significant improvement compared with commercial regenerated cellulose materials. In addition, these materialsalso showed excellent durability and reusability performance owing to the strong chemical crosslinking structure between fibers formed in modification process and stable chemical propertiesof cellulose.This kind ofprotein adsorption nanofibrous membranes are expected to be widely used in various fields, containing pharmaceuticals and disease diagnosis.

This work is supported by the National Natural Science Foundation of China, the Shanghai Committee of Science and Technology, the Fundamental Research Funds for the Central Universities, and the “DHU Distinguished Young Professor Program”.